Facebook Marketplace is a dangerous place. You know the story; it’s late on a Saturday night, you’re cruising FB Marketplace just for the hell of it. And then you see it – that one thing that catches your eye.

My first mistake was stopping to look at it.

But like a good movie, it’s time for a flashback. While one of the cars in my current stable is a 1965 Sunbeam Tiger, I’ve always loved the Sunbeam Rapier Fastback, and I’ve owned a few over the years, but sold my last one when I bought the Tiger. Just didn’t have space for two of them (more likely it was my wife saying she didn’t want me to start collecting cars).

When I owned a Sunbeam Rapier Fastback in the 1990s, I had always thought how awesome that car would be with a Rover V8 in place of the Rootes Group 1725cc four-cylinder. That 4-pot engine is okay, especially when it’s mated to a 4-speed with electric-overdrive gearbox, but it’s a little noisy – rattly if I’m being honest – and could easily do with more power and smoothness. That’s one of the reasons that the Sunbeam Tiger grew out of the Sunbeam Alpine it’s based on when Carrol Shelby pulled the 4-cylinder out of an Alpine and put a 260 Ford V8 in it.

And that’s why I had always thought a Rover V8 engine would be the perfect motor for this car. It’s light at just 10Kg more than the 1725cc 4-cylinder, it’s smooth, sounds good and parts are readily available.

My aim then, and has always been, is to stick a Rover V8 in that Fastback body to make a comfy and smooth grand tourer.

Project V8 Rapier Fastback: Body Design

For many years, the design of the Sunbeam Rapier Fastback was not popular. It just looked a little weird to so many people. I was the opposite and have always loved the shape. Wind down those windows on the pillarless design, and it looks stunning in my eyes. And guess what? It’s now a cool shape, and this has been reflected in the prices of even rusted-out Fastback wrecks going for thousands of dollars.

Of course, as anyone who has started and finished a project knows, this isn’t about making a profit. I’m not sure anyone in the history of time has ever made a profit from a project car.

For me, this is about actually doing something I’ve always wanted to do, end of story.

Project V8 Rapier Fastback: Back To The Present

Flashback over, there I was cruising Facebook Marketplace when I spied it. A Rover V8 engine for sale, complete with a Rover 5-speed manual gearbox. The motor and ‘box are out of an SD1 Rover since that’s the only one that came out with a 5-speed. I’d been casually keeping an eye out for an earlier 4-speed manual ‘box, as I haven’t seen a 5-speed for sale for decades, if ever. And that is one of the main reasons I stopped in my tracks at this advert; 5-speed Rover gearboxes are like hen’s teeth. Sure, I could just buy a Rover V8 engine and stick a Toyota ‘box behind it, but to get both together was screaming out ‘buy me!’ from the screen.

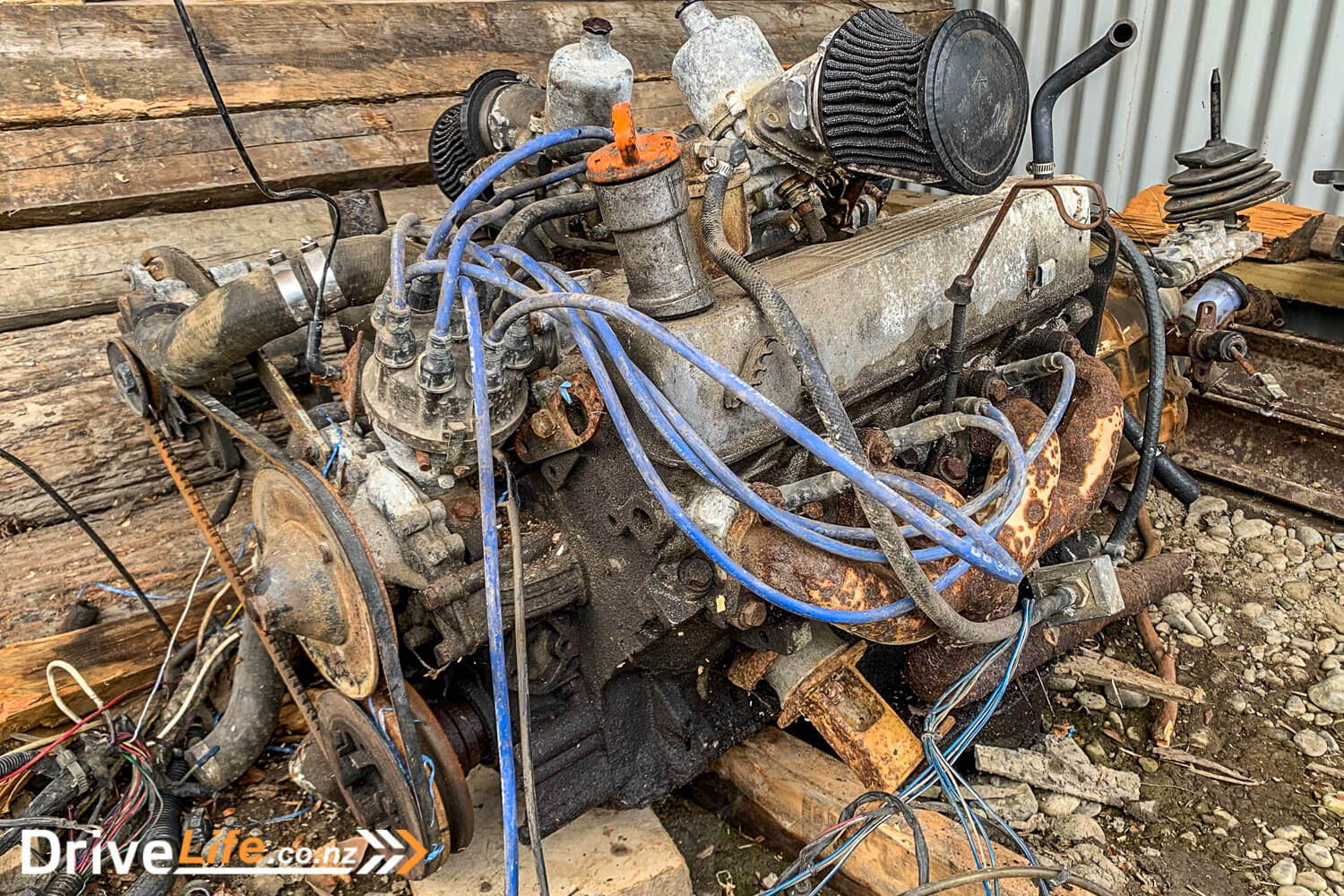

But the photos of the engine and gearbox did not look good. Covered in leaves and crap, it looked like they had been sitting there for decades, not weeks as was suggested in the ad. Thoughts of the engine being seized sprang to mind. You’ve got to think of worst-case scenarios when looking at a motor that seems to have been forgotten for many years.

I made contact with the seller (my second mistake) and asked for more photos and info. He insisted that the engine had only been sitting for a few weeks, and had been pulled out of a Datsun ute beach hack. The chassis on the Datsun had rusted away, but the motor and ‘box were worth keeping.

Project V8 Rapier Fastback: Purchasing A Donor Engine

After going back and forth with messages, I decided it was time to go take a look at the engine in Rongotea, a 2-hour drive away. A great chance to get my C4 Corvette out of the garage, where it’s been sitting for the last three months without being driven. I got to Rongotea and met the seller in town and headed to where the engine and ‘box were stored.

Honestly, they didn’t look quite as bad in the flesh as in the photos, and I could turn the motor over by hand, so definitely not seized, and that was a huge selling point for me. Another bonus was that it looked like most things were there, including some of the wiring loom, starter, alternator etc. It really did look like a complete unit.

We settled on a price of $500 for both the motor and ‘box, and I headed home. Without being able to do a compression test and/or oil pressure check, I didn’t want to pay any more than that.

Project V8 Rapier Fastback: There Go Five Years

On the way home, I realised just what I’d done; I’d committed to a project car. Idiot!

I’ve heard so many times of people starting a project car, and never finishing it. One guy I heard of recently has ten project cars, has found out he has cancer and just 12 weeks to live. This was another reason I decided to do this project; I’ve always wanted to do this, and what is the point of leaving it any longer?

But I need to be realistic. I’ve now got an engine and gearbox, but that’s the easy part. I still need to consider things like:

- Certification

- What diff and how to mount it?

- Mounting the engine, transmission

- Cooling

- Brakes

- Suspension changes

- Electrical

Will it really take 5 years? I hope not, but I don’t want to set unrealistic expectations. I’ll aim for three years but who knows. COVID might even jump in here and cause delays too. You just have to look at Rob’s UR Audi Quattro project as an example of how much longer it can really take.

Project V8 Rapier Fastback: Getting The Engine Home And Mounted

Ona Friday night, I borrowed some muscle and a van and we headed to Rongotea and grabbed the engine and box. Easier said than written, but we got it home to my garage in a five-hour trip.

After a brief clean, it didn’t look as bad. I borrowed (very long-term borrowed!) an engine stand from fellow motoring journalist, Alistair Weekes. Having it on the stand would mean I could wheel the engine outside, and give it a proper clean-up with some degreaser and elbow grease. You can see from the photos that it’s still going to need a lot of TLC cosmetically, let alone a rebuild if it needs it.

But – will it start? Can I drip-feed some fuel into it, change the engine oil and hook up a coil and a 12-volt battery, and start it? All will (hopefully) be revealed in Part 2. It will either be cheers or tears, and I’m not putting money on either at this stage. It might be a good time to hook up an oil-pressure gauge to see how good (or bad) that is.

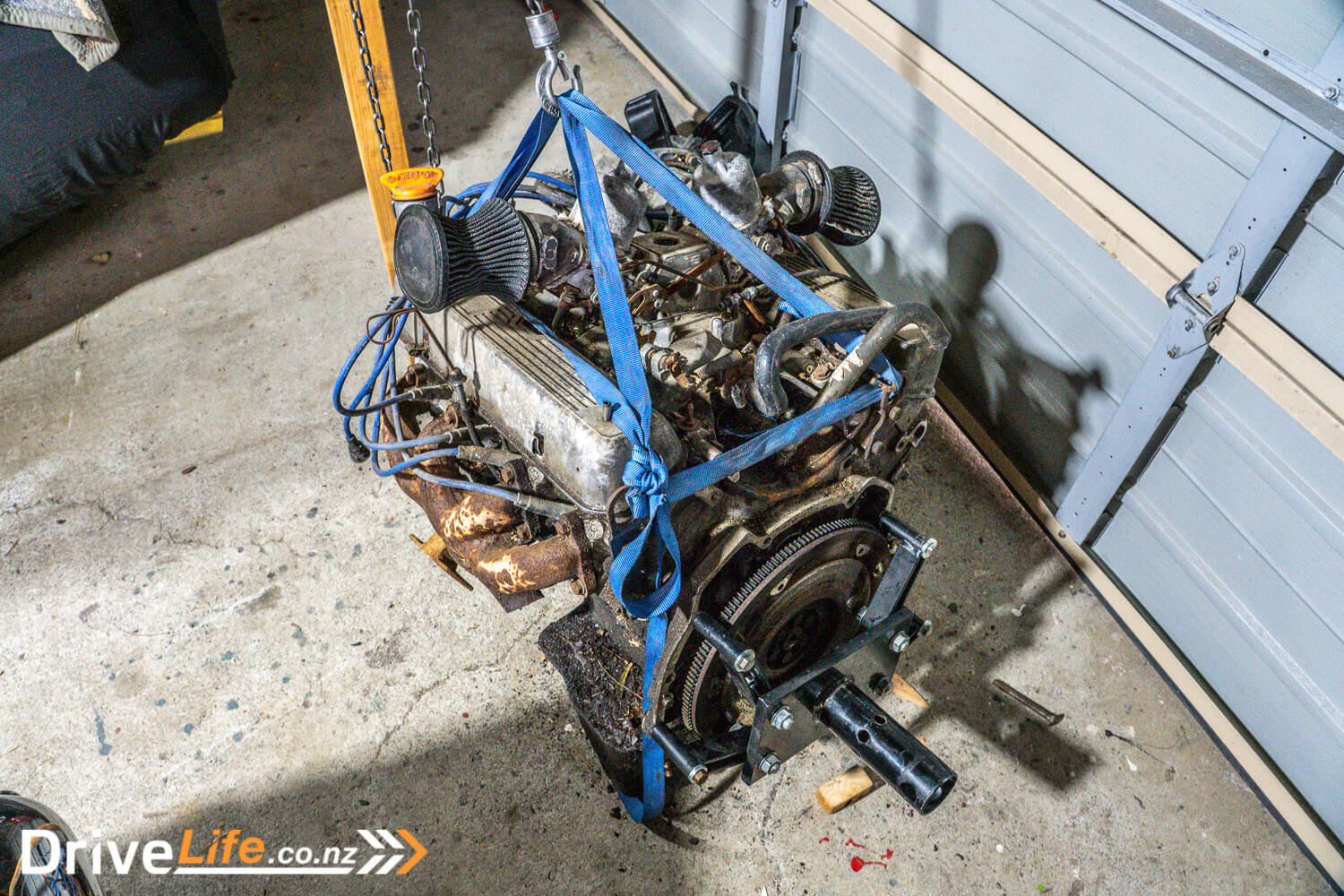

Regardless, one Sunday some friends and I took to the spanners and split the engine off the gearbox, which meant all of thirty minutes. My memories of having to muck about to break the seal between an engine and gearbox dissipated, and I thought it was looking like this might be an actual easy job.

But no. The bell housing bolts were too short to bolt the engine to the mount of the stand, so it was mucking about searching for some bolts long enough. Of course, we found three bolts, but not a fourth. With 140Kg pulling on the mount, four bolts are a must. Thirty minutes later, and we found an odd bolt that fitted.

So that was it, lift the engine? Not yet. The chain block had an eye at the top, but we had nothing in the beam in my garage to hook it up to. After much deliberation, someone went and grabbed a 2-ton strop, and we attached it to the beam, and then the block to the strop. We added a piece of 4×2 to support the beam and lifted. From there on, it was easy work. We got the engine to the right height for the stand and slid it in. It was all over very quickly.

Now my engine is mounted on wheels, and I can take my time (and save my back) by cleaning it up on an engine stand. It will make life a lot easier.

Project V8 Rapier Fastback: Donor Car

At least there’s one thing I can tick off already; a donor car. For around 25 years I’ve had a Sunbeam Rapier Fastback parked in my (dry) garage 1,000Km north at Ahipara, west of 90 Mile Beach. It has an engine and gearbox, but the car isn’t road legal, so I can’t drive it home.

Also, it’s in a garage way into the bush, so to get it out is going to need a 4WD with low range and diff locks, not to mention a car trailer. One of the corners getting to my house is called ‘Jackknife Corner’, to give you some idea of just how bad the road is. When we parked it in the garage, the road was a lot better!

And that’s not to mention that it’s a 1,000Km drive from Wellington to where the car is – and then another 1,000Km to return home with the car on a trailer.

So, is getting the car going and driving it home an option? Nope – the rego is dead. It’s a bit of a long story, but before the internets you could only keep the rego alive while the car was off the road by sending in a form. NZ Post sent my form to the wrong address, so the rego on my Fastback lapsed. Renewing that is going to be another potentially painful part of this project.

But there is light at the end of the lapsed-rego tunnel. In conjunction with VTNZ, DriveLife will be publishing an article early in the new year on the entire process of bringing your rego back from dead. Keep an eye out for this article, or better still, join our newsletter list so you can’t miss it.

Project V8 Rapier Fastback: A Rover V8 In A Sunbeam Rapier Fastback Engine Bay?

Now you might be asking, will a Rover V8 fit into that Fastback body that was never designed for a V8 engine?

Another short slice of history; When the idea of the Sunbeam Tiger was being born, a service manager from a Rootes Group dealership in Los Angeles walked around car yards with a piece of wood (a yardstick), and this is how he checked any V8 engine he came across would (or wouldn’t) fit into the Sunbeam Alpine engine bay. He found the Ford 260 V8 to be suitable, and light (around 200kg).

Fast forward 57 years, and I was on a car rally in Levin and so was someone in a Sunbeam Rapier Fastback. We were at a beach as part of the rally, so I grabbed a piece of driftwood I thought was long enough and caught up with the Fastback driver, opened his bonnet, and marked my driftwood with the edges of his strut towers.

By a stroke of luck and maybe some experience, the piece of driftwood was around 3 inches too long at each end – perfect. Marks in place, I checked the Rover V8 when I got home, and as you can see, there’s plenty of room for the motor to go into the Fastback engine bay. My own little piece of history being made, right there. I still have the driftwood and have mounted it in my garage as a token of the start of this project. It will be the cheapest part of the project, of that there is no doubt.

Project V8 Rapier Fastback: The Body

I’d love to tell you the body on my donor car is perfect, or even good, but it’s not. There’s rust in the usual places for a British car.

And here comes my second part of the plan; I want to resto-mod this car. I’m thinking black and chrome, maybe remove the bumpers and also change the front and rear of the car to modernise them. How will that look? I have no idea yet, but I want this car to be a head-turner. Low and mean, black and chrome. Tint all the windows to the max legal level, and I’d love to shave the exterior door handles and boot-lid button to make it more streamlined and less cluttered.

Mechanical changes? One thing I’ve lusted after is sticking a Holley Sniper in place of the Rover’s SU carbs. A Holley Sniper is a replacement bolt-on electronic fuel injection system; you take your carb/s off the manifold and essentially bolt the self-contained Sniper into its place. The engine runs smoother, is much more efficient, and definitely more reliable. A Sniper is not cheap, but so worthwhile. Holley also sells a matching electronic distributor that ‘talks’ to the Sniper, thus making it even more efficient, and by proxy, more powerful.

I know I need to create a spreadsheet to track the money I am going to spend on this project, but 90% of me doesn’t want a spreadsheet. It will be horrific, and I’ll have to hide it from my wife.

Project V8 Rapier Fastback: Next Steps

The most difficult part of this whole project will be that I need to sell my Sunbeam Tiger. This is extremely painful for me, as it’s all original, hasn’t even done 100,000 miles yet in its 56 years on the road, and it rolled out of the Jensen factory gates the same day I came out of hospital as a newborn baby (true story). I have every receipt for this car since it was new. Selling it is going to take a lot of willpower and angst, but I need the space in the garage and the cash in the bank to complete this project. Out of the 7,000 or so Tigers they built, only around 1,000 were right-hand drive, so it’s a rare car, and so that (sadly) should make it easier to sell.

After that, the next step will be getting the Fastback from its ‘barn find’ status in the Far North and back to my garage in Wellington.

Over the next who knows how long, it will be getting the engine into the car, getting it certified and renewing the registration, and perhaps even a WoF. Will it need some sort of change of suspension/steering/brakes before that? No idea. After that, the engine and box can come out, and then it’s on to body restoration and modifications, and interior update.

I’m going to take the opportunity to update the interior somehow; I’ve always loved a bit of wood in the interior, so may go for a classy wood and leather look but modern, ideally with some luxuries like power windows, door locks, and mirrors. But again, who knows? The sky (and a budget) is the only limit here.

As part of this series of articles, we will be engaging with the Low Volume Vehicle Technical Association (LVVTA). We will seek their input, advice, and use one of their members for the certification process where the V8 Fastback project car needs it.

I’ll be straight up and say I’ve never undertaken a project car to this level before, and mistakes will be made. Hopefully, those mistakes will be minimised (both financially and time-wise) with the help of LVVTA. If you have always dreamed of doing a project car, we hope you will learn from our mistakes.

The biggest help will likely come from the LVVTA’s New Zealand Car Construction Manual, a 500-page PDF to help with every section of any build. It is gold, and I will be referring to it often. You can download it for free here. While it’s over 500 pages long, there are only certain sections that I need to refer to, like engine modifications, suspension, steering, and anything else that needs certification.

Project V8 Rapier Fastback: LVVTA – Who Are They?

The Low Volume Technical Association (LVVTA) administers modified vehicle standards and the Low Volume Vehicle certification system on behalf of Waka Kotahi (NZTA). The NZ Government (through Waka Kotahi) requires that all vehicles meet applicable safety requirements, and once a vehicle is modified above a certain level from its original state (or is scratch-built), there needs to be a method of ensuring continued compliance with these safety requirements.

Nearly thirty years ago, a small group of car enthusiasts started a passion project with the aim of safeguarding the right to build and modify cars, which has grown into a contract with Waka Kotahi to provide a system of technical requirements and useful how-to guidance for vehicle modifications. These range from typical performance enhancements (engine conversions, brakes, suspension, wheels, etc) to seat installations, seatbelt anchorage retrofitting, right-hand drive steering conversions, removal and disabling of supplementary restraint system air-bags, security modifications for security vans, through to adaptive control systems for people with disabilities, and designing modifications to remedy factory faults in production vehicles.

The LVVTA-led system incorporates over 40 LVV Certifiers around the country, a head office with twelve permanent staff in Porirua who process LVV certifications, provide technical help and support for LVV Certifiers and vehicle modifiers, and a wealth of publicly available documents that outline the requirements a modified vehicle must meet in order to be safe, and therefore LVV certified.

Each year around 6,000 vehicles are LVV certified by a nationwide network of LVV Certifiers. Training and support of these LVV Certifiers, with a focus on consistency, is a key part of LVVTA’s daily business, as is developing appropriate legal standards as vehicles and modification styles evolve. Just like their customers, the LVV Certifiers and LVVTA head office staff all live and breathe modified vehicles and are passionate about the LVV system, all understanding the freedom it allows for fellow enthusiasts.

The purpose of the LVV certification system, therefore, is to ensure all modified production vehicles (whether modified for commercial, passenger service, disability, recreational, leisure, sporting, or compliance purposes), and scratch‐built vehicles, have been designed and constructed in such a way that they are safe to operate on the road and comply as closely as practicable with the legal safety requirements applied to high volume production vehicles.

We’re looking forward to watching the progress of Project V8 Fastback; this sounds like it has the potential to be an exciting and very usable classic car and a great tribute to a car that Rootes Group never (but probably should have) built. Initial indications are that there will be several aspects of this project covered by LVV requirements: the engine swap of course, seats, and seatbelts, but also potentially brakes, steering, and suspension. We’ll be working with DriveLife’s LVV Certifier where required throughout the build process, to ensure that all modifications meet LVV requirements and make sure that the whole process goes smoothly.

Project V8 Rapier Fastback: Part 1 done

This was the easy bit; buying an engine and telling you what we’re about to do. I’m wondering if it’s time to set up a Give A Little page, but we’re hoping to take advantage of New Zealand’s awesome auto parts suppliers and services and do a complete and fully detailed article on each step of this project car.

Stayed tuned for updates as this project moves (slowly) along.

Brilliant Fred! I look forward to following this.

Before you buy the Holley Sniper I have some advice to pass on.

HI Ray. Thanks for the comment and I’d be keen to catch up and chat about the Sniper in due course.

I will be following this project with interest. Looking forward to reading about the sale of the Tiger too. Cheers, Bill