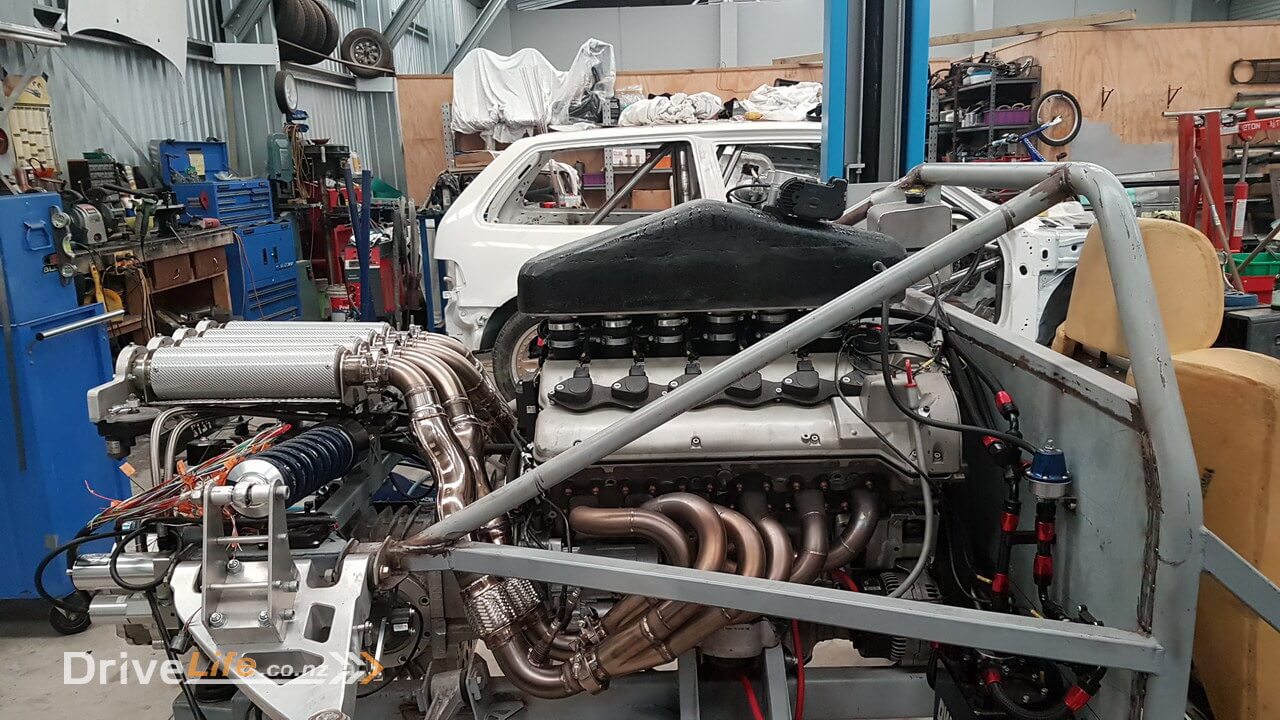

It’s been a long time coming, but we’re finally able to reliably start, run and rev the engine in the FZ12.

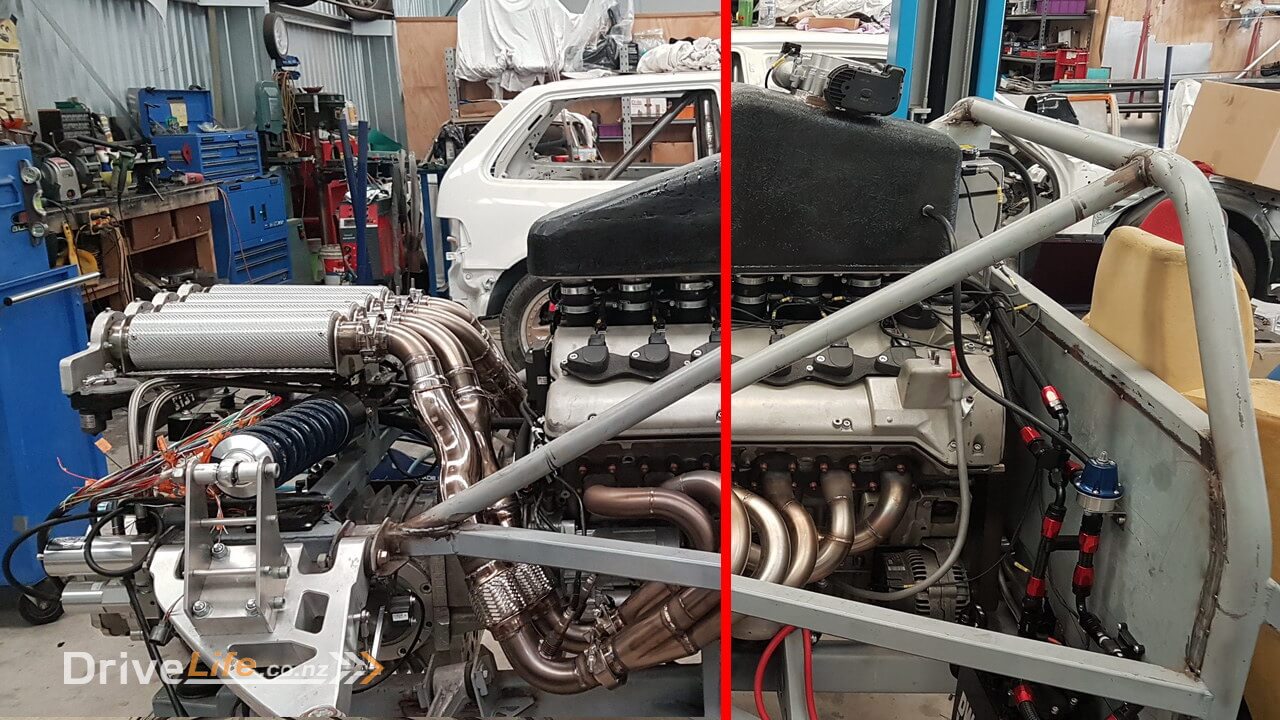

I won’t keep you in suspense too long, but we did have one change to make to help us get there and that was that the temporary intake plenum we made was way too big. We needed to get the size down to help control the throttle inputs. At the end of episode 33 I showed the process we took to reduce the size of the intake. Here is the reduced size plenum for comparison, installed and ready to go.

OK, here it is……… our V12, starting, idling and revving. As always with these things, it sounds so much better in person, but for now this is the best I can do. I will try to get some more video with a dedicated microphone too, but it does sound pretty good on my laptop.

Please excuse me being in the video, but it just goes to show that you don’t have any mates till the cool car is finished !

Hope you enjoy it as much as I do !

Please feel free to comment or ask questions, I really love sharing and discussing our build and cars in general with other readers.

There’s a newer entry in this story, please click here – FZ12 – Part 36

If you’ve missed the last part of our story then click here FZ12 – Part 34

or if you want to go right to the beginning then click here FZ12 – Part 1

Hi Fraser, I don’t have much to say I have been following this series from the beginning and it is great to see the engine running! Keep up the good work and I can’t wait to see the final article!

Hi Stuart, Thanks for following and commenting. It’s always really nice to know that people are getting something out of what we’re doing and I enjoy following other peoples builds just as much as doing my own !

It really is great to have the engine running so sweetly and we’re pushing along with getting most of the mechanical side of things mocked up so that we can get the Low Volume Vehicle inspection guys to come and take a look and hopefully give us the OK to finish the welding etc and move onto the bodywork side of things !

Mate. That sounds so good. What a pleasure, you must be a proud dad to have brought the beast to life.

Not so far to go now.

Thanks Graham. It’s such a shame it doesn’t come across on video, but it person it’s even better ! Can’t wait to get it finished and on the road………going to be mental !

I’ve been following the build and I’m a great admirer of your work. I believe the transaxle is usually flipped in a street application to reduce axle shaft angles. I don’t remember reading anything about this in your posts, just thought I would mention it.

Hi Scott, Thanks for your comments. It’s always nice to hear that readers are getting something out of our posts. I’m not sure what you’re getting at with flipping the transaxle for street applications. The only time I’ve heard of flipping a transaxle is all of the Porsche G50 and other type transaxles that need to be flipped since Porsche run the engine behind the transaxle, but most people need to flip it to run the engine in front of the transaxle.

We’re not using a Porsche transaxle, we’re using a custom made Mendeola transaxle. We do have some drive shaft angle, but the CV’s are rated for up to 26 degrees of angle without any issues and we have around 15 degrees maximum at full compression so we’re well within tolerance. We could have run the transaxle lower, however because we’re running a flat bottom that would have meant we would have needed to raise the engine and I didn’t think the trade off was worth it.

Thanks for reading 🙂

Greetings!! You guys are doing an awesome job, I’m actually from Miami, where the body is from. I’m venturing to create my own car as well and want to use a Mercedes V12 . I had a few questions regarding the programming of the engine to make it run. How did you guys bypass all the other engine parameters to make the engine run? I want to use the M120 or the newer M275. I’ll give you more info whenever I have the opportunity to hear back. Thank you and continue the great work.

Hi Joby, The M120 in particular is basically 2 engines running off a single crank. Mercedes took 2 of their successful 6 cylinder engines and put them on the same crank and basically ran them as 2 separate engines. Each side of the engine had it’s own ECU and it’s own set of sensors. 2 crank sensors, 2 cam sensors etc etc. I think at the time, ECU’s weren’t capable of running a V12, so they had to split it down into 2 x 6 cylinders instead. Now we are using an EMTRON KV12 ECU which can talk to the engine as a single unit. We are only using a single crank sensor and we had to remove one of the cam sensors and magnets to make it only have one pickup point for the cam timing but apart from that it’s pretty straight forward. Using the factory equipment was never an option and it’s close to 30 year old tech too so not a good idea.

I suspect that the newer engines would already have a single factory ECU, but again, you would probably be best to look to run a completely separate aftermarket ECU like the EMTRON KV12 or Motec M150.

Thank you for the reply, what email can I use to directly email you? I have a few more questions and didn’t want to use up all this precious webpage ☺️

Hello! Brendon from California. Im taking on a rather ambitious build here, taking the m104 6-cylender out of my 95’ e320 Wagon, and swapping in a m120 engine. Since a kid i was obsessed with the Zonda, from the C12 to the F and so on. The sound is unbeatable and a Zonda is currently unibtainable, so the next best thing for me is to take my favorite body style wagon produced by mercedes and use the heart of the Zonda to create my dream car, ive been curious about the exhaust, as i want it to sound like the Cinques and those with Titanium exhausts rather than the raspier early models, the titanium sounds so tighrlt strunf and fine tuned. As i get closer to the exhaust portion of the build is there any way I could get in touch with you directly to pick your brain on how you got this beast to sound as good as the Zonda, and also the hurtles you overcame and improvements you made on this engine? I would love to talk with another head-over-heels enthusiast like myself about this. I can be reached at [email protected], send me a Hello! Thanks for your time brother.

Hey Brendon,

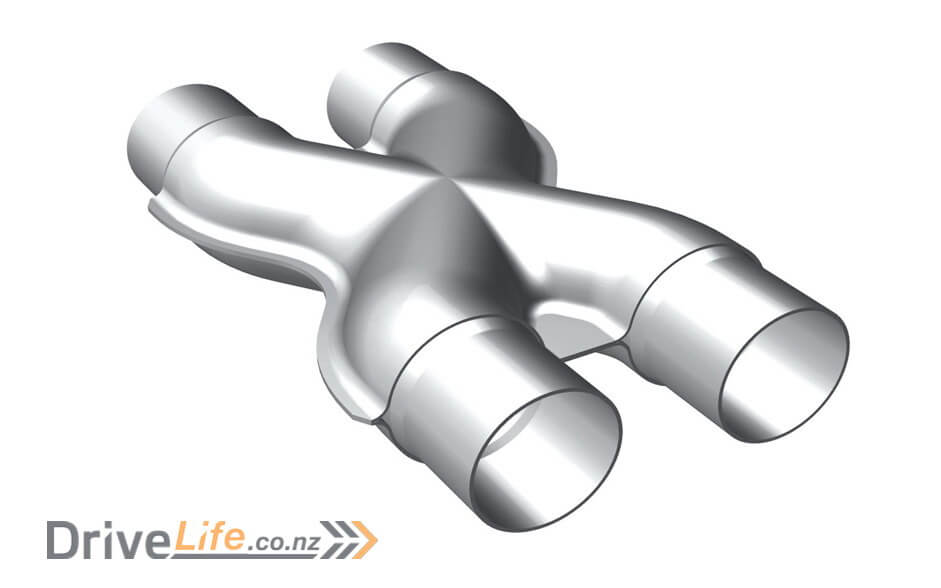

I’ll send you a separate e-mail. To be honest we used a lot of different photo’s of the Zonda R – F etc to see how Pagani had done it. Also I recently watched a documentary about the CLK GT1 which also used the M120 and their manifolds look really similar to the Pagani one, so I suspect the main differences in the exhaust sound are really down to the section after the main manifolds. That section is really going to come down to your material choices, muffler design and how you’re forced to run the exhaust because of packaging reasons.

As mentioned I’ll drop you an e-mail so you can contact me directly and I’ll see if I can help where I can 🙂

Thanks for following our build.

hey Fraser, I’m hoping to pick your brain about the emtron unit and base settings you used to get the motor running, also wondering why you didn’t use the factory coils. can you shoot me an email? Thanks! [email protected]

Hey Fraser, watched your progress since you received the body. I’m interested in sourcing two of the “muffler barrels” you are using. I really like the sound they allow. Could you please let me know the name and type they are, would love to have a pair of those. You send the info via email at [email protected]

Thanks in advance, Looking forward to seeing this supercar driving.