It’s great to be finally getting to the stage where I’m having to consider things like brake and power steering fluid etc as it’s a sign we’re getting close to this car being able to move, stop and steer under its own power, one of those rare watershed moments in such a build.

With that said however, it turns out that this isn’t as straightforward as it would usually be, surprise surprise ! The reason is down to the fact that because the front end of this car is so low, it doesn’t leave any headroom for the fluid reservoirs to sit above the items they need to feed. These are usually gravity fed and so have to sit above the items they feed or else the fluid will never make it there.

With the lack of headroom a clear issue the only real solution was to move the reservoirs to the rear of the car where I could mount them higher than the brake, clutch, power steering etc. It does mean I have to have long pipes to take the fluid down the side of the car, but technically there is no reason this can’t work and to be honest it’s my only option. So the next step was to design something up in Fusion 360 and get O.L.S to laser cut it and then ask Zac nicely to TIG it up for me so it was nice and tidy.

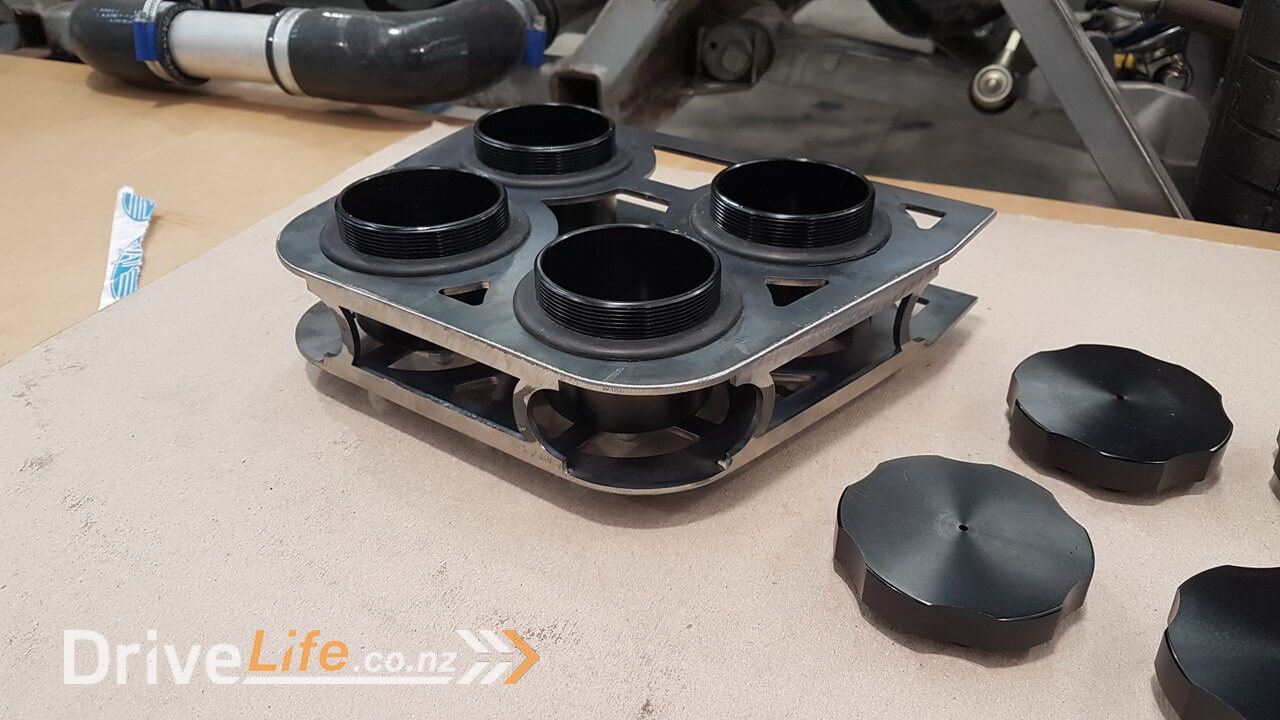

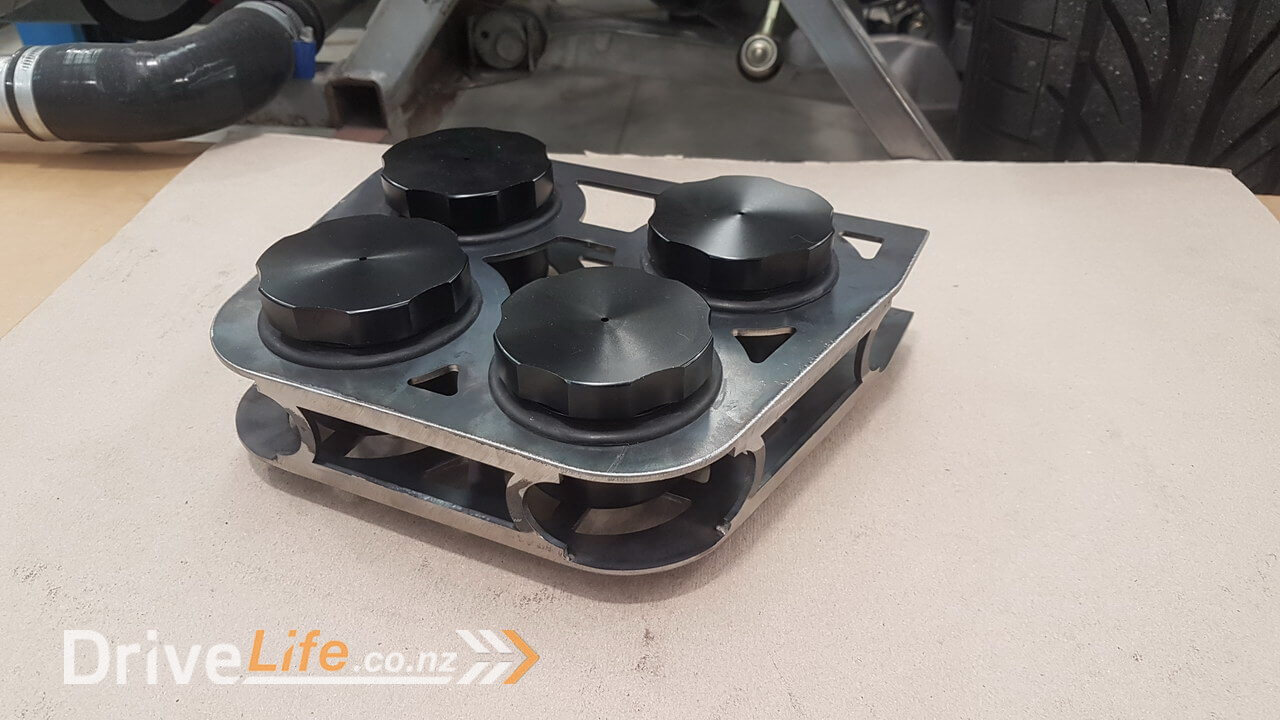

We started off by welding in some steel fittings to the bottom plate. The top side of the fittings are where the reservoirs themselves fit to and the other side has a standard AN6 fitting where the braided line will run to feed the units at the front of the car.

Despite all of the holes cut into this unit, it still ended up heavier than I’d like due to being made from steel, but I felt it was the easiest choice to make rather than making it from aluminium and then having to make some kind of mounting mechanism to mount it to the chassis itself.

The reservoirs have a o-ring seal on the bottom to help seal against the fitting, however there is no real pressure in these reservoirs so it’s not super critical.

There is one for the brake / clutch fluid, one for the power steering / brake booster and the other 2 are for the ride height pump which allows the car to have a computer controlled ride height as it will need quite a bit of fluid.

The reservoirs themselves were actually really cheap ($12 each) but I think they look great and are really nicely finished. Next I needed / wanted to find a nice clean seal for them. I hunted high and low to find someone that made a perfect side rubber seal and could only find one place in the USA and I needed to buy 20 for them to bother to sell them to me as they were a manufacturer not a retailer. They were really good about the pricing though so it made it worth while, but needless to say I’ve now got a lifetime supply of them !

The lids of the reservoirs came with a really nice little rubber seal too, so all in all I’m really happy with the end result.

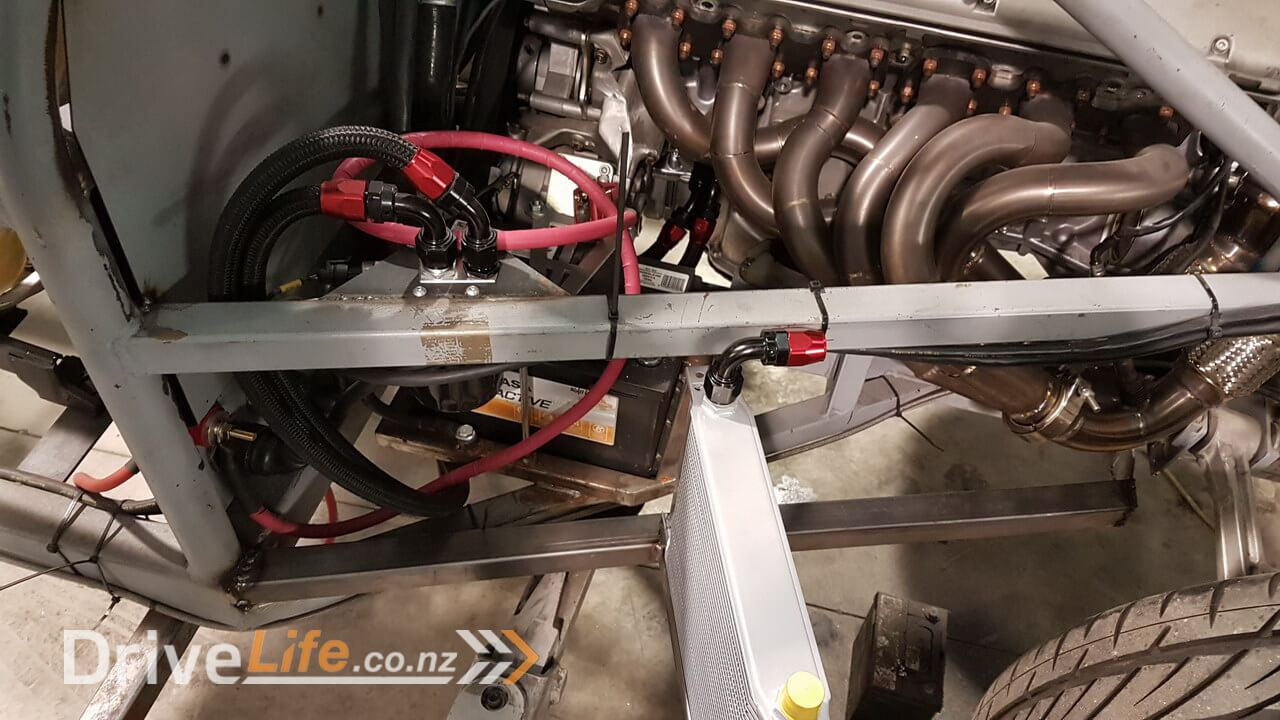

Next it was just a matter of tack welding it to the chassis behind the driver and we’re ready to run lines to the front.

The lines run down the side of the car. They’re a bit messy now since I haven’t made any clamps to hold them, but once they’re made they will have to hold the pipes every 300mm in line with the LVVTA regulations.

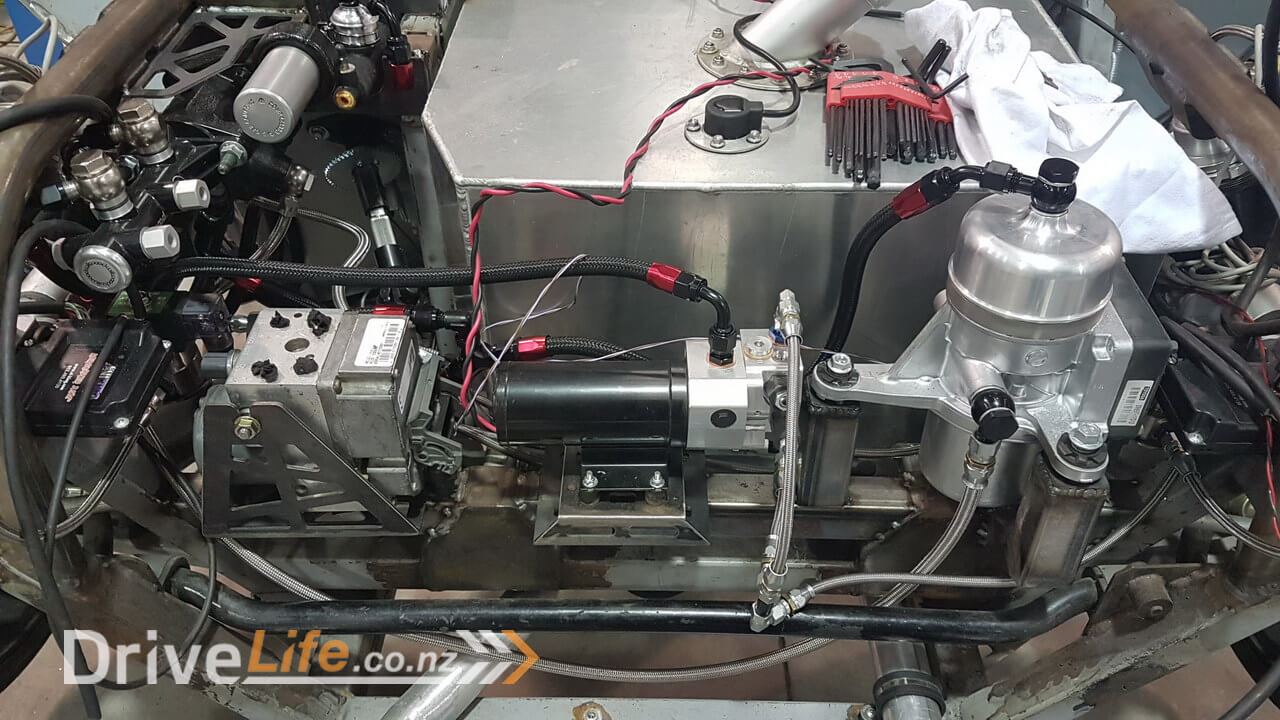

Everything is all being fed now apart from the clutch as we don’t have the clutch hydraulic release bearing fitted until the new gearbox turns up, but we’ll run a line ready for it. Here you can see the power steering and ride height pump feeds. The last part of the puzzle is to fit the hard and braided brake lines to the ABS pump, but I’ll cover that in a separate episode. It’s starting to look busy up front, but we will tidy it up once we know it all works.

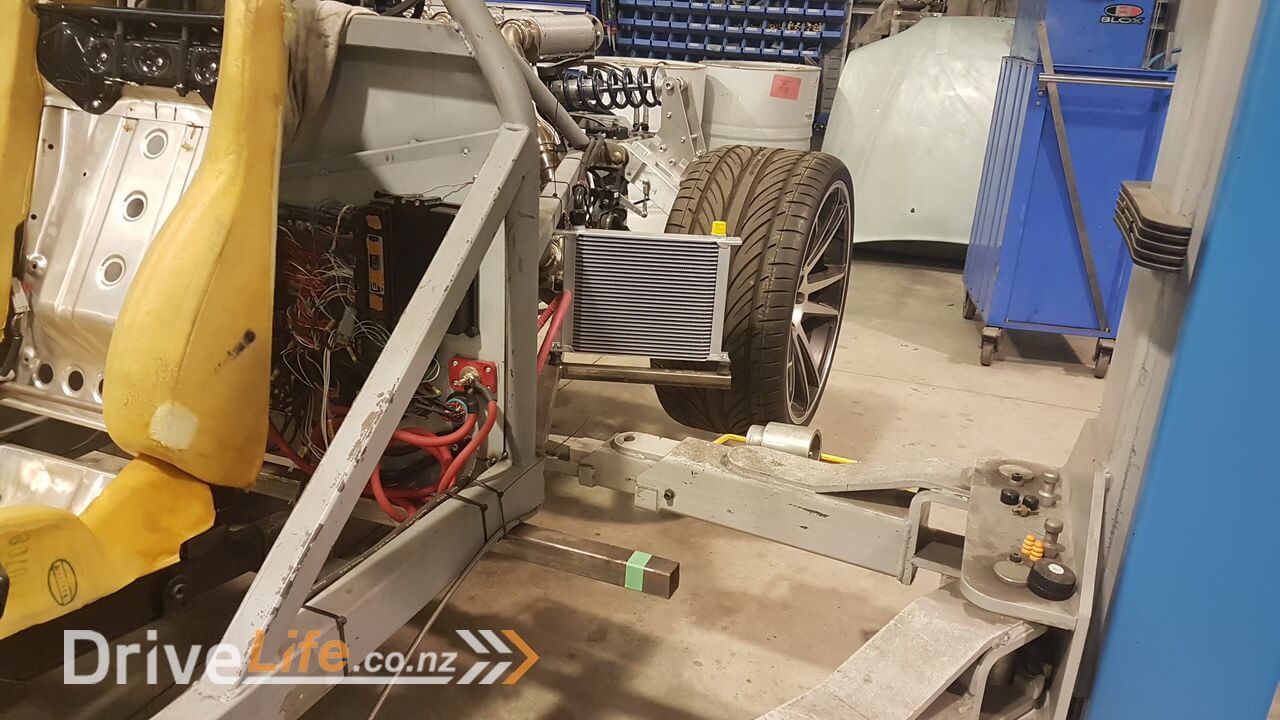

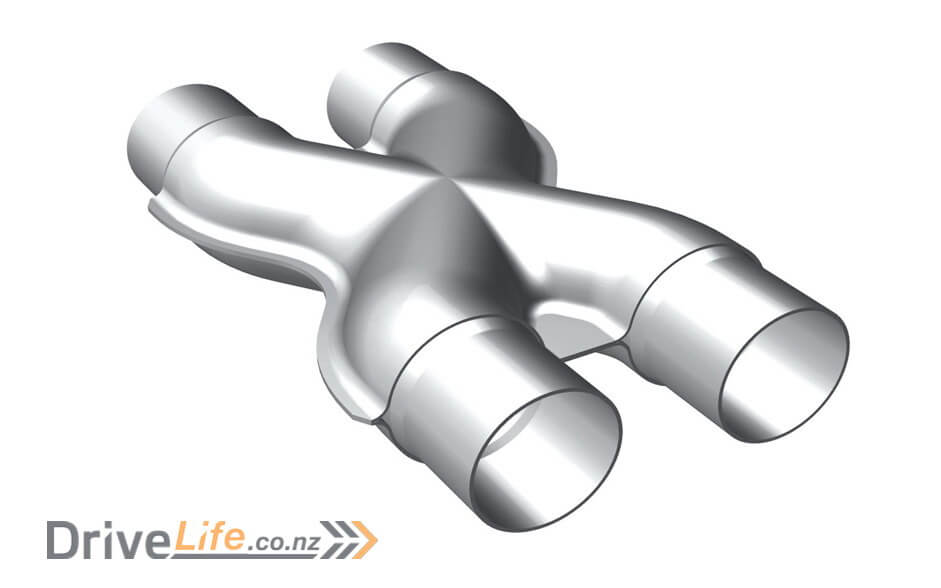

Another area that I got onto was to fit the oil cooler. It’s not required for operation at the moment and might not be required for operation at all, but it’s easy to fit and it seems pointless to not fit one to cover things considering it might not run so cool once it’s closed in with bodywork.

It’s not plumbed into the oil system yet, but it’s only a matter of making up a couple of braided lines which is a 10 minute process, but I don’t think I’ll bother with that until we put it back together for the final time (it’s still got to be fully disassembled yet).

Please feel free to comment or ask questions, I really love sharing and discussing our build and cars in general with other readers.

If you’ve missed the last part of our story then click here FZ12 – Part 38

or if you want to go right to the beginning then click here FZ12 – Part 1

What a project! I have thoroughly enjoyed reading the posts but do have a question. What Honda ignition coils are you using and what was needed to make them fit. Any information on this is welcome..feel free to email. Thanks.

I did cover the coil packs in an earlier episode, they are from a Honda J series engine. Model code is J32A2, but I am pretty sure that a lot of the J series engine share the same parts. I just happened to have some sitting around for our race car project and tried them to see and they fit perfectly ! Then it was just a matter of getting the plate laser cut and making a couple of small spacers for the bolts and that’s it.

Hope that’s helpful ? Thanks for following.

Thanks for the info…sorry if I missed it.

I forgot to mention in my initial comment that the engine sounds phenomenal. It is amazing how good this engine sounds when you replace the factory manifolds with proper headers. I bet she’ll scream once driving.

Keep up the good work and I look forward to following along the project.

How’s the project going? I’ve veen following from the start and it feels like another update must be due soon.

Hi Danny, Project has kind of stalled in the last couple of months to be honest, not due to anything other than having the time to make progress. As is the case with most people doing these kind of projects, it’s not a full time thing, it’s really just about getting time where and when you can to move ahead.

The biggest issue has been Xmas as usually I don’t go away, but this year we did so I lost a lot of time I’d usually get on it over the Xmas break.

With all that said though, there will be some updates coming up as there has been progress, but none are complete so I didn’t want to write a post about something half done, but I have a few half done things for one reason or another. As I said though, the project hasn’t died and there will be progress soon 🙂

Thanks very much for following and glad you have got something from what we’ve done so far.

Fraser

Fraser, any chance you can share the part number for the connectors and terminals used on the Honda ignition coils?

Thanks.

Hey mate. I don’t have a specific part number, but if you search for K20, K24, J30, J35 coil plug etc they’re all the same. Just a quick search on Ebay found this. It’s where I got mine from. https://www.ebay.com/itm/4x-Honda-K-Series-K20-K24-3-Pin-Ignition-Coil-Pack-Connector-Plug-Housing/283236027860?hash=item41f22ecdd4:g:cnYAAOSw~RFa53Yn:rk:16:pf:0 There may well be cheaper around, I just searched Ebay for just the plugs itself rather than ones with wires, like pigtails as I didn’t want to join onto their crappy wire.

hows it going

When’s the next part coming out? Haven’t seen any in a while!!

Looking forward to seeing the next one at some stage 🙂

Best of luck

Yeah sorry guys……….. we have been working on our NSX race car and it’s taking a bit longer to get completed than expected with the Xmas break etc and then getting back up to speed again………..

The FZ12 project is not forgotten, but I have limited time and resources (only one car lift) and we need it for the NSX at the moment so once that’s done we’ll be getting the FZ12 back up to speed and producing some more content…….

Thanks for following…… keep the faith 🙂

Wondering the same. I have been checking almost daily for updates. Hope you are well Fraser.

Hello Fraser, any updates on the FZ12 project?

Very interested from 🇨🇦!

Take care

Would you be willing to sell or provide a copy of the technical drawing of the M120 bellhousing with crank centerline?

Hi Timothy,

Sorry but I don’t have any CAD drawings for the adaptor. It was just made by hand as we planned on making an aluminium one later on, but we had some steel and wanted to be sure it was right before making an aluminium one later. Once we do that we will have drawings as we’ll scan the steel one in now we know it’s right, but that won’t be for a while I’m afraid.

Fraser

Hi Timothy,

Sorry but I don’t have any CAD drawings for the adaptor. It was just made by hand as we planned on making an aluminium one later on, but we had some steel and wanted to be sure it was right before making an aluminium one later. Once we do that we will have drawings as we’ll scan the steel one in now we know it’s right, but that won’t be for a while I’m afraid.

Fraser

Hi Fraser!

how´s the build going, any updates?